High Standard Calcium Chloride Desiccant Powder

Model No.︰CODE-50B

Brand Name︰chunwang

Country of Origin︰China

Unit Price︰US $ 0.3 / pc

Minimum Order︰1000 pc

Product Description

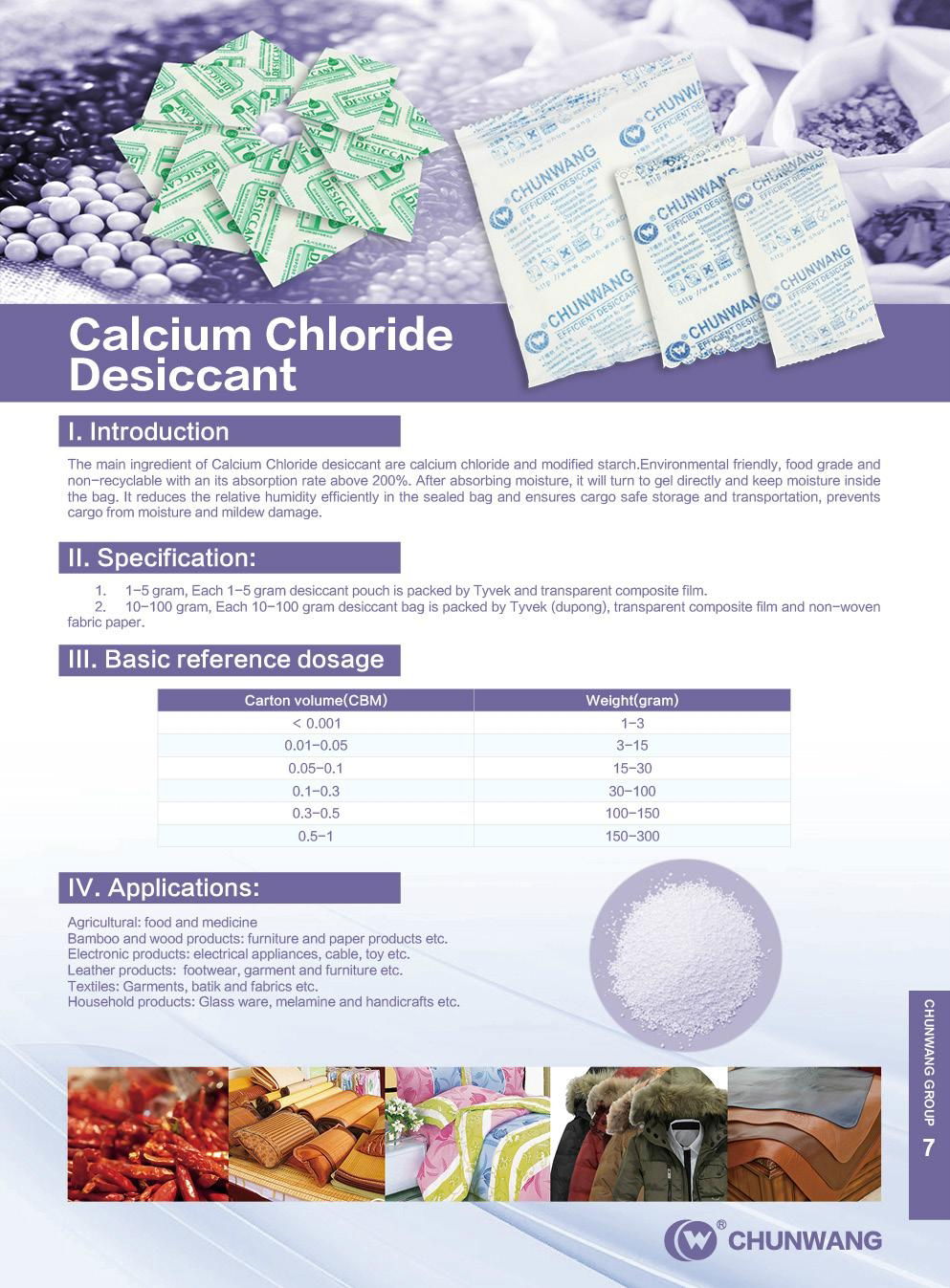

CHUNWAGN calcium chloride desiccant is widely used by well-known enterprise of various industries for its superior absorption rate, special safety formula and fresh package design.

Main ingredient: Calcium chloride

Calcium chloride desiccant pouch is a kind of environmental friendly, food grade and non-recyclable desiccant. The absorption rate is above 200%. After absorbing moisture, CHUNWANG calcium chloride desiccant will turn to gel directly and keep moisture inside the bag. It reduces the relative humidity efficiently in the sealed bag and ensures cargo safe storage and transportation.

Protect cargo from moisture, mildew.

Specification: 1-5gram,10-100gram

Each 1-5gram desiccant pouch is packed by Tyvek (dupong) and printing composite film.

Each 10-100gram desiccant bag is packed by Tyvek (dupong), composite film and non-woven fabric paper

Application:

Agricultural: food, medicine

Bamboo and wood products: furniture and paper products etc.

Electronic products: furniture and paper products etc.

Leather products: foodware, garment and furniture etc.

Metal products: Cils, machinery, auto/spare parts, copper products and furniture etc.

Textiles:Garments, batik and fabrics etc.

Household products: Glass ware, melamine and handicrafts etc.

Special Feature and Advantage

Dual layer package leakage free design: Inner layer:

Tyvek outer layer:high grade non woven materials.Dual layer ensure no leak in the contact surface.

The most advanced one way venting packing materials:Inner sac one way tyvek,outer sac one way high grade non woven fabric papper.

Chun-wang Tips

The damage of moisutre to various items

1.Optical lenses: According to Japan's portrait of the industrial experiment, precise optical lens is easy to breed mold on the Coating Optical long-term moisture adsorption, especially in the 60%RH environment, the lens once suffer the mold, we can not see in our eyes, even if repaired, it can not restore the original sharp degree, with loss of a recording / detection / on deviation and repair, therefore automatic humidity control should be in 30 ~ 50%RH.

2.Paper,woodworks,textile,leather products: They all contain a lot of cellulose, long-term moisture swelling deformation will affect the quality of precise printing; moisture sticky dust fouling, color fading. Automatic humidity control should be in 30 ~ 50%RH.

3.Tobacco,tealeaf,food,medicine: These materials are very easy to absorb moisture,it will cause caking, taste, color, moldy, metamorphism and even carcinogenic toxins (such as: aflatoxins, ochratoxin Coffee peanut... ) Automatic humidity control should be in 30 ~ 50%RH.

4.Precision metal products: From watches, precious metal jewelry, silver, metal crafts, model cars, tools, gold,collectives to precise mold / tool / gauges industrial tooling / equipment (pieces)... ... Its precision machining (carving) metal surface is easy to absorb moisture and lead to oxidation (especially 35%RH above), it my cause loss of gloss / corrosion, fouling and adhered with dust, and the impact of value to the collectives. Automatic humidity control should be under 40%RH.

Payment Terms︰ TT/LC/Paypal/

Product Image